Products

![]() Energy conservation / Complete combustion of gas

Energy conservation / Complete combustion of gas

Infrared radiators radiantly transmit heat without interfering with the air in the middle but directly into the object.

![]() High frequency of radioactivity

High frequency of radioactivity

The total energy of gas is about 70%, which can transform infrared heat rays with high thermal efficiency. The traditional gas stove only puts 30% infrared heat rays.

![]() Orientation free

Orientation free

The orientation of the infrared gas burner can be changed arbitrarily.

![]() High durability and long life

High durability and long life

The lifetime of using the infrared gas burner is longer, and it can be used continuously more than 20,000 hours ,with the economic benefits.

![]() Low expenses

Low expenses

The heat is transferred by radiation, so there is no need to add cooling or low-cost heat exchangers.

![]() Environmentally friendly clean equipment

Environmentally friendly clean equipment

When using infrared gas burner is no need to blow the indoor air for heating, no dust which is good for human health.

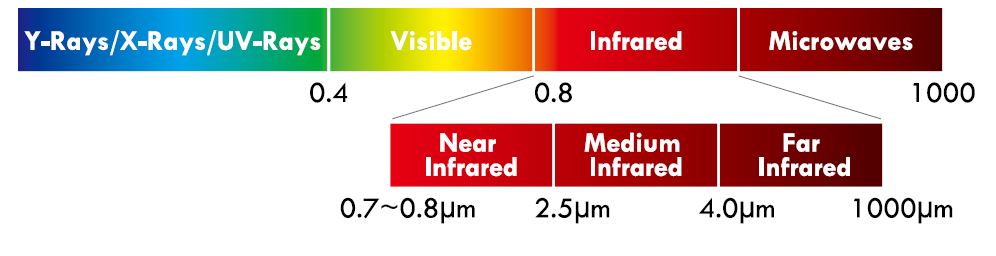

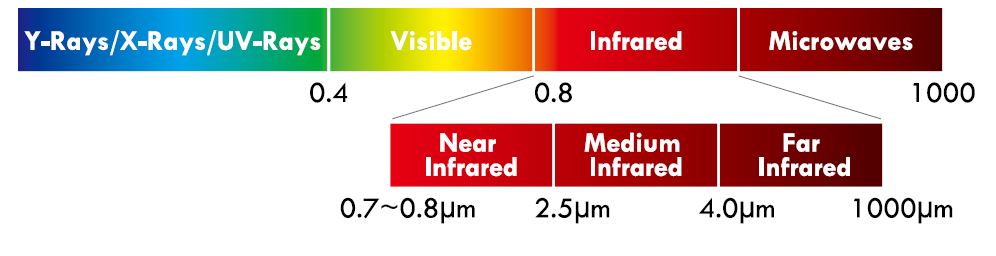

![]() Appropriate Waves used

Appropriate Waves used

where infrared appears on the electromagnetic spectrum:

Waves (µm)

Special precautions for user

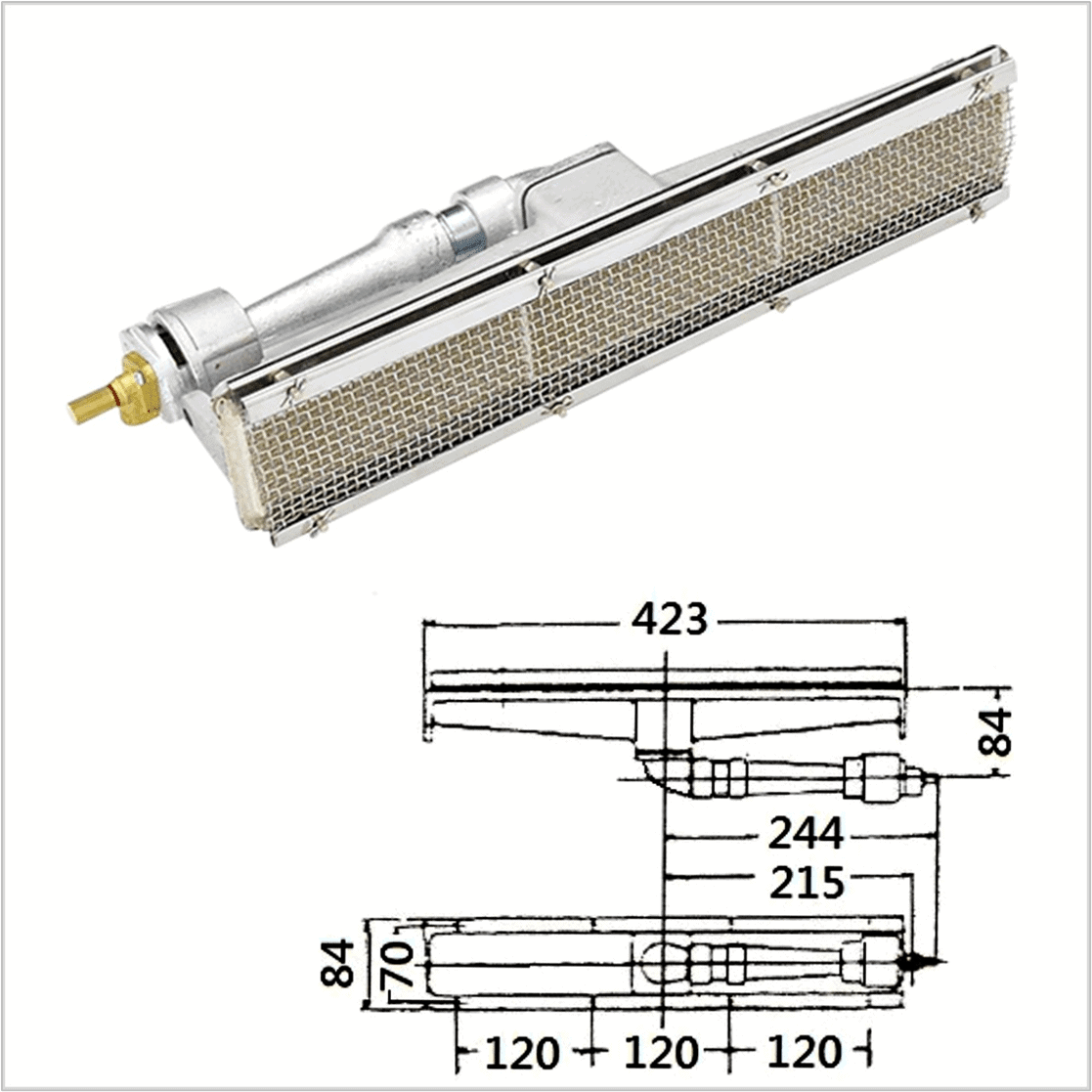

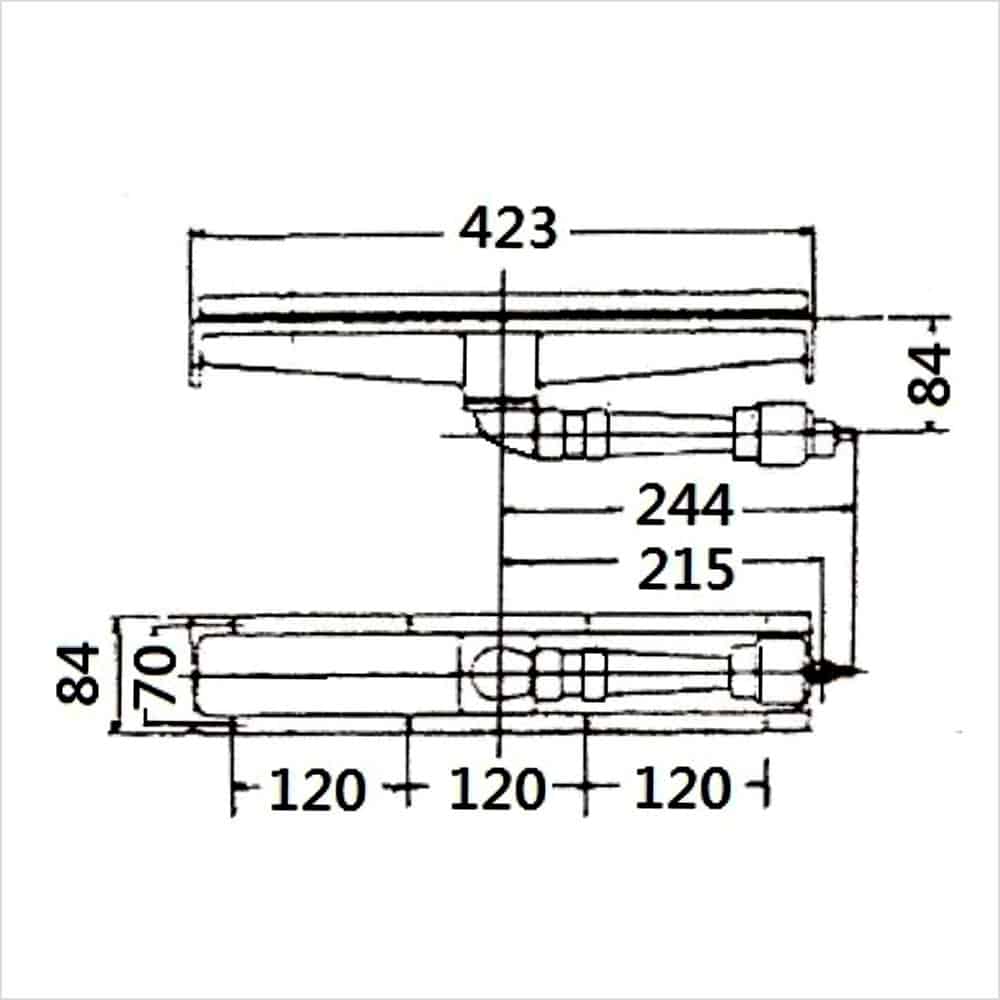

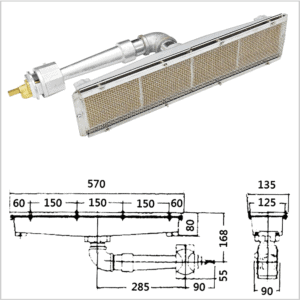

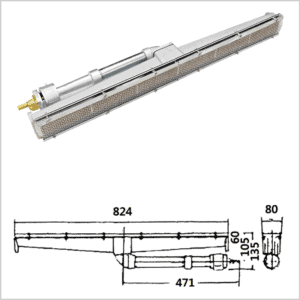

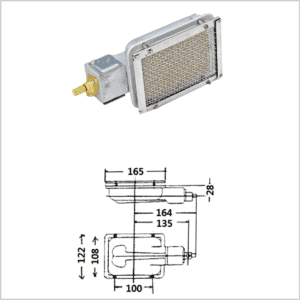

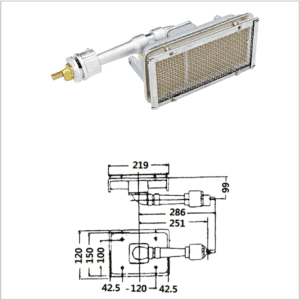

1. Please consider the width, size, and temperature of the stove base to choose a model. The surface temperature of the burner K-1602 can reach above 800°C. The burner K-1602 is the Top1 of the high frequency of radioactivity.

2. When purchasing, please indicate the type of the gas is NG or LPG.

4. Before leaving the factory, the gas and air mixing ratio of this infrared burner has been adjusted. Please do not move the damper at will. This product belongs to the all-one-air combustion method, that is, the amount of air required for combustion is all provided by one-time air, so good ventilation must be maintained in the field of use to successfully achieve a complete combustion state.

5. The infrared ceramic plate is fragile, and please avoid collision.

6. If the infrared burner has abnormal sound during use, please check whether the pressure exceeds the allowable range or check whether the pottery on the stove surface is damaged. These are the two main reasons for the abnormal sound. If the burner will not be used for a long time, please pack it in a box to keep the body clean.

8. Please avoid the sauce dripping on the pottery when grilling. When purchasing, you can confirm whether it is used for upper fire or lower fire (when the furnace surface is up, it is lower fire). When used for fire, the temperature limit is 550 degrees to 600 degrees. When used for fire, it is no problem if the temperature is above 700 degrees.

(1) Food industry: grilled meat, sausages, biscuits, grilled chicken...etc.

(2) Painting industry: baking varnish, preheating, and pickling for drying.

(3) Agriculture and animal husbandry: chickens, birds for warm-up.

(4) Ceramics industry: drying molds.

(5) Dyeing industry: dyeing and drying.

Products

![]() Energy conservation / Complete combustion of gas

Energy conservation / Complete combustion of gas

Infrared radiators radiantly transmit heat without interfering with the air in the middle but directly into the object.

![]() High frequency of radioactivity

High frequency of radioactivity

The total energy of gas is about 70%, which can transform infrared heat rays with high thermal efficiency. The traditional gas stove only puts 30% infrared heat rays.

![]() Orientation free

Orientation free

The orientation of the infrared gas burner can be changed arbitrarily.

![]() High durability and long life

High durability and long life

The lifetime of using the infrared gas burner is longer, and it can be used continuously more than 20,000 hours ,with the economic benefits.

![]() Low expenses

Low expenses

The heat is transferred by radiation, so there is no need to add cooling or low-cost heat exchangers.

![]() Environmentally friendly clean equipment

Environmentally friendly clean equipment

When using infrared gas burner is no need to blow the indoor air for heating, no dust which is good for human health.

![]() Appropriate Waves used

Appropriate Waves used

where infrared appears on the electromagnetic spectrum:

Waves (µm)

Special precautions for user

1.

Please consider the width, size, and temperature of the stove base to choose a model. The surface temperature of the burner K-1602 can reach above 800°C. The burner K-1602 is the Top1 of the high frequency of radioactivity.

2.

When purchasing, please indicate the type of the gas is NG or LPG.

3.

The standard gas pressure for infrared gas burner is 280 ± 50mmH2O.

4.

Before selling, the mixing ratio of gas and air has been adjusted; please do not move the air door of the infrared gas burner.

5.

The infrared ceramic plate is fragile, and please avoid collision.

6.

If the infrared burner has abnormal sound during use, please check whether the pressure exceeds the allowable range or check whether the pottery on the stove surface is damaged. These are the two main reasons for the abnormal sound. If the burner will not be used for a long time, please pack it in a box to keep the body clean.

7.

If there is a blue floating fire on the burner may due to insufficient gas pressure. Please adjust the pressure to 280 ± 50mmH2O.

8.

Please avoid the sauce dripping on the burner surface when grilling. When purchasing, you can confirm whether it is used for upper or lower fire (when the burner surface is up, it is lower fire). When using of the upper fire, the temperature has limit which is 550 to 600 degrees. When using of the lower fire as normal, the temperature can easily achieve above 700 degrees.

9.

Applicable industries:

(1) Food industry: grilled meat, sausages, biscuits, grilled chicken...etc.

(2) Painting industry: baking varnish, preheating, and pickling for drying.

(3) Agriculture and animal husbandry: chickens, birds for warm-up.

(4) Ceramics industry: drying molds.

(5) Dyeing industry: dyeing and drying.